Short Run Metal Stamping: 10 Smart Reasons to Choose It for Your Next Project

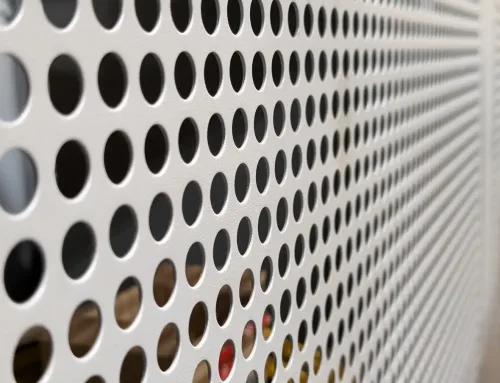

Short run metal stamping is one of the most efficient ways to produce high-quality metal parts when you don’t need massive volumes. It’s especially valuable for prototypes, product launches, engineered components, and low-to-mid production runs where flexibility, speed, and precision matter.

At Fox Valley Stamping, short-run stamping is treated as a strategic manufacturing solution—not a compromise. Below is a clear, practical breakdown of why short-run metal stamping is often the smartest choice and how to decide if it’s right for your project.

Short-run metal stamping is ideal for low-to-medium volume production when you need tight tolerances, fast turnaround, and lower tooling costs than long-run stamping. It’s commonly used for prototypes, design iterations, and production parts that may evolve over time.

What Is Short Run Metal Stamping?

Short run metal stamping produces precision metal parts in smaller quantities, typically ranging from a few hundred to several thousand pieces. Instead of investing in expensive progressive tooling designed for millions of parts, short-run stamping relies on flexible tooling and efficient press setups.

This approach allows manufacturers to maintain quality and repeatability while keeping costs and lead times under control—especially during early production phases.

10 Reasons to Choose Short Run Metal Stamping

- Lower Tooling Costs

Short-run tooling is simpler and less expensive than progressive dies used for high-volume production. This significantly reduces upfront investment and financial risk.

- Faster Lead Times

With fewer tooling steps and streamlined setup, short-run parts can move from design to production quickly—ideal for tight timelines and fast-moving projects.

- Tight Tolerances Without High Volume Commitment

Modern presses and precision tooling allow short-run stamping to achieve consistent tolerances suitable for many industrial and OEM applications.

- Ideal for Prototypes and First Production Runs

Short-run stamping lets you produce functional parts using real manufacturing processes. This reveals design or tolerance issues before scaling up.

- Design Flexibility

Engineering changes are easier and more cost-effective in short-run projects. Adjustments can often be made without scrapping expensive tooling.

- Consistent Quality Control

Smaller batch sizes allow closer inspection and process monitoring, helping maintain consistent quality from the first part to the last.

- Reduced Material Waste

Short-run layouts are optimized for efficiency, minimizing scrap and supporting more sustainable manufacturing practices.

- Material Versatility

Short-run stamping works well with:

- Steel

- Stainless steel

- Aluminum

- Brass and copper alloys

Material selection can be adjusted to balance strength, corrosion resistance, formability, and cost.

- Easier Transition to Full Production

Short-run projects often serve as a bridge to long-run stamping, allowing designs and processes to be validated before scaling.

- Cost Control for Variable Demand

If demand is uncertain or seasonal, short-run stamping avoids overproduction while keeping per-part costs predictable.

Short Run vs. Long Run Metal Stamping

| Feature | Short Run Stamping | Long Run Stamping |

|---|---|---|

| Typical Volume | Hundreds to thousands | Tens of thousands to millions |

| Tooling Cost | Lower upfront | Higher upfront |

| Flexibility | High | Limited |

| Lead Time | Faster | Longer setup |

| Best Use | Prototypes, evolving designs | Stable, high-volume parts |

Short-run stamping prioritizes flexibility and speed. Long-run stamping prioritizes lowest cost per part at scale.

When Short Run Metal Stamping Is Not the Best Choice

Short-run stamping may not be ideal if:

- You require extremely high volumes with no design changes

- Per-piece cost must be minimized above all else

- The part requires complex progressive tooling optimized only for mass production

In those cases, long-run or progressive stamping may be a better fit.

Common Questions About Short Run Metal Stamping

How many parts qualify as a short run?

There’s no fixed rule, but most short-run projects range from a few hundred up to several thousand parts, depending on complexity and tooling.

Can short-run stamped parts meet tight tolerances?

Yes. With proper tooling, press selection, and quality controls, short-run stamping can meet many precision requirements used in industrial and OEM applications.

Is short-run stamping good for production parts?

Absolutely. Many production components are intentionally kept in short-run quantities to allow design flexibility or manage fluctuating demand.

Can short-run projects scale to long-run production?

Yes. Short-run stamping is often used to validate part design and manufacturability before investing in high-volume tooling.

Why Work With Fox Valley Stamping?

Fox Valley Stamping specializes in short-run and precision metal stamping, supporting customers from early design stages through repeat production. Their approach focuses on manufacturability, quality, and long-term scalability—helping customers avoid costly mistakes early in the process.

Whether you’re launching a new product, refining a design, or managing variable demand, experienced short-run support makes a measurable difference.

Ready to Get Started?

If your project requires precision, flexibility, and fast turnaround without the cost of high-volume tooling, short-run metal stamping may be the right solution.

👉 Contact Fox Valley Stamping to discuss your part design, material needs, and production goals—and get expert guidance tailored to your application.