10 Types of Press Tool Operations: A Complete Guide for Manufacturers

Here are 10 essential press tool operations that power modern manufacturing:

1. Blanking

Blanking cuts out a flat shape (blank) from sheet metal.

The blank becomes the finished part or is used for further processing.

- Produces precise part outlines

- Minimizes burrs and edge defects

- High repeatability

Common parts: washers, discs, gears, decorative components

Industries: automotive, aerospace, electronics

2. Piercing

Piercing punches holes or shapes into sheet metal.

- Produces circular and non-circular holes

- Often combined with progressive die stamping

- Increases efficiency by eliminating secondary drilling

Common parts: ventilation holes, fastener locations, electrical cutouts

Industries: HVAC, appliances, control panels

3. Shearing

Shearing cuts sheet metal along straight lines or defined shapes.

- Prepares blanks for other operations

- Trims edges and cuts materials to size

- Supports high-precision sheet preparation

Industries: metal fabrication, industrial equipment, aerospace

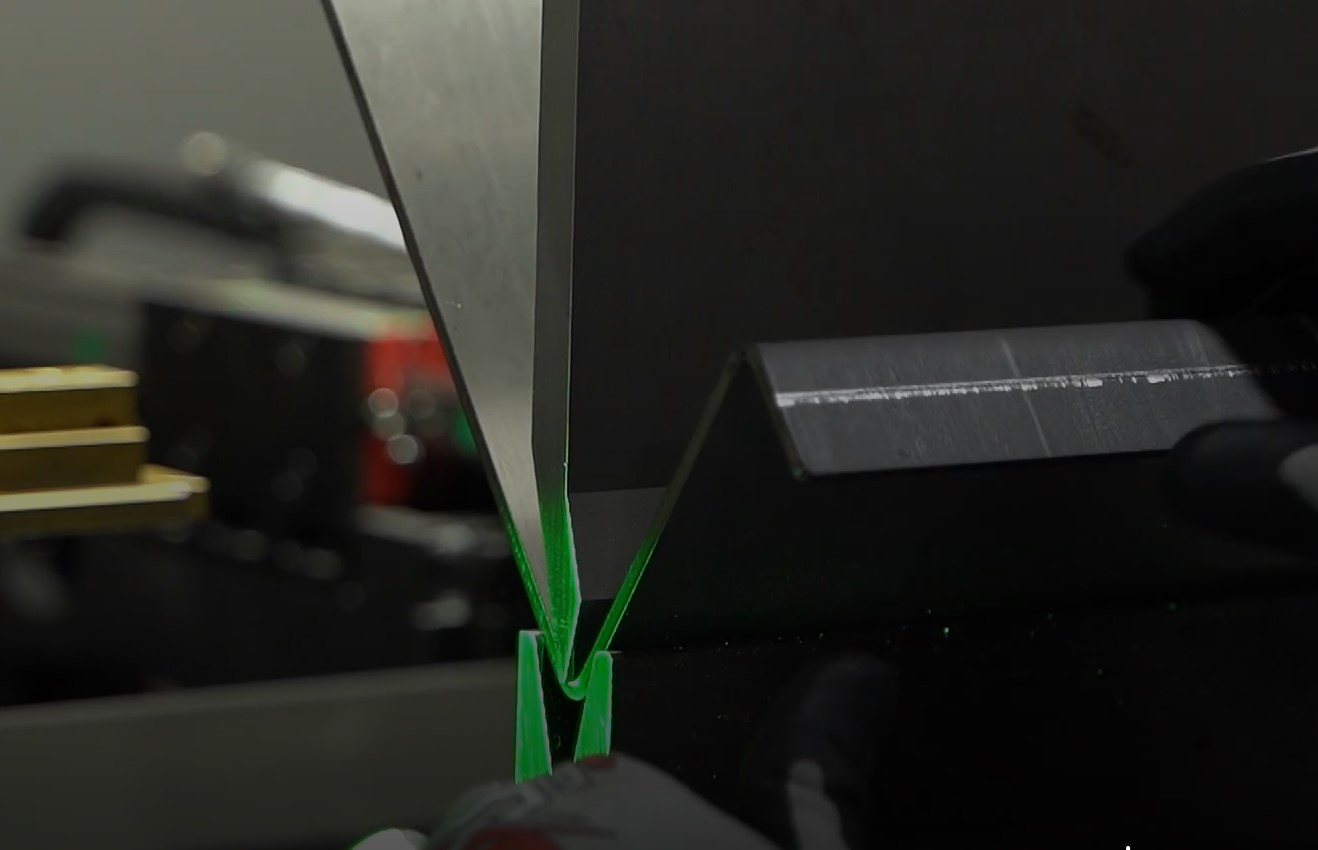

4. Bending

Bending deforms sheet metal along a straight axis.

- Creates angles, flanges, channels

- Critical for structural and enclosure components

- Achieves consistent bend radii and tolerances

Common parts: brackets, chassis, enclosures

Industries: electronics, appliances, automotive

5. Drawing

Drawing pulls metal into a deeper, three-dimensional shape.

- Produces seamless cups, boxes, enclosures

- Deep drawing achieves significant depth without rupture

- Often eliminates welding or assembly steps

Common parts: auto body panels, kitchen sinks, electronic housings

Industries: automotive, consumer products, appliances

6. Forming

Forming reshapes sheet metal without cutting it.

- Includes embossing, flanging, coining, curling

- Adds structural or decorative features

- Improves part strength and function

Common parts: decorative trim, stiffened panels, reinforced features

Industries: electronics, appliances, industrial controls

7. Coining

Coining applies high pressure to refine features.

- Creates fine details, sharp edges, and smooth finishes

- Produces precision logos, text, and intricate patterns

- Increases dimensional accuracy

Common parts: connectors, washers, decorative parts

Industries: electronics, medical devices, consumer products

8. Embossing

Embossing raises or depresses portions of sheet metal.

- Adds logos, branding, textures, or functional features

- Improves stiffness and visual appeal

- Often combined with progressive die stamping

Common parts: nameplates, branding elements, structural embossments

Industries: enclosures, appliances, aerospace

9. Notching

Notching removes material from sheet metal edges or interiors.

- Prepares edges for joining, assembly, or clearance

- Enables snap fits and mechanical fastener access

- Increases design flexibility

Common parts: structural assemblies, HVAC ducting, frames

Industries: construction, industrial equipment, automotive

10. Lancing

Lancing creates cuts that form attached tabs or louvers.

- Forms ventilation louvers or snap-fit tabs in one operation

- Reduces need for secondary assembly

- Adds functionality with minimal added cost

Common parts: HVAC panels, lighting fixtures, enclosures

Industries: HVAC, electronics, lighting, appliances

Key Factors to Consider

When selecting press tool operations, consider:

✅ Part complexity and geometry

✅ Material type and thickness

✅ Tolerances and surface finish requirements

✅ Production volume and cycle times

✅ Tooling investment and lead time

✅ Need for secondary operations (deburring, plating, assembly)

Fox Valley Stamping can help you evaluate these factors to choose the optimal solution for your project.

Applications and Industries That Benefit

Press tool operations drive production excellence across industries:

-

Automotive: body components, fasteners, clips

-

Aerospace: lightweight structures, precision components

-

Medical devices: housings, surgical parts, instruments

-

Consumer appliances: covers, frames, decorative parts

-

Industrial equipment: guards, enclosures, machine components

-

Electronics: connectors, EMI shielding, chassis parts

FAQ: Press Tool Operations

What is the difference between blanking and piercing?

Blanking removes a full shape from sheet metal, creating the part. Piercing creates holes or cutouts within the part.

When should I use deep drawing vs. forming?

Choose deep drawing for parts requiring significant depth (cups, boxes). Use forming for adding shallow features like flanges or embossed details.

What tooling lead times should I expect?

Simple tools can be ready in 2–4 weeks. Complex progressive dies or deep drawing dies may require 8–12 weeks. Early collaboration helps reduce lead time.

Can multiple operations be combined?

Yes. Progressive die stamping combines multiple operations in one tool, improving efficiency and reducing costs.

Which industries benefit most from precision metal stamping?

Automotive, aerospace, medical, electronics, consumer products, and industrial equipment manufacturers rely heavily on press tool operations for cost-effective, high-volume production.

Partner with Fox Valley Stamping

Fox Valley Stamping delivers expert metal fabrication services, optimized press tool operations, and collaborative engineering support to help manufacturers:

✅ Improve product quality and precision

✅ Reduce production costs

✅ Shorten lead times

✅ Achieve scalable high-volume production

From progressive die stamping to deep drawing and complex forming, we help you choose the right solution for your unique application.

👉 Contact Fox Valley Stamping today to request a quote, schedule an engineering consultation, or discuss your next project.

Fox Valley Stamping provides precision metal fabrication, advanced press tool operations, and expert engineering support for manufacturers across automotive, aerospace, medical, electronics, and industrial markets. Learn more about our services »