Metal Stamping Types and Custom Solutions

When it comes to manufacturing metal components, stamping is one of the most efficient and versatile processes available. From simple brackets to highly detailed electronic parts, metal stamping makes it possible to create durable, precise components in both high and low volumes.

But not all stamping methods are the same. Manufacturers can choose between several types of metal stamping, and many projects require custom metal stamping to achieve exact specifications. This guide breaks down the basics, the types of stamping available, and how custom services can meet unique industry needs.

What Is Metal Stamping?

Metal stamping is the process of shaping flat sheets of metal into specific forms using stamping presses and dies. The sheet—often called a blank—is pressed, cut, or formed into a part.

This method is widely used because it is:

- Cost-effective for large volumes

- Flexible, supporting both simple and complex designs

- Efficient, with fast production times

- Consistent, delivering identical parts with tight tolerances

Common stamping techniques include:

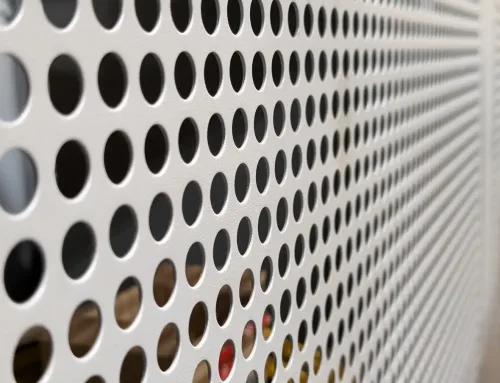

- Punching – removing sections from sheet metal

- Blanking – cutting a clean piece of metal from a larger sheet

- Bending – forming angles and curves

- Embossing – creating raised or recessed designs

- Coining – applying high pressure for fine details and smooth edges

- Flanging – forming flared or rimmed edges

Types of Metal Stamping

Depending on the application, manufacturers choose the stamping process that best balances strength, precision, and cost. Here are three of the most common methods:

1. Hot Metal Stamping

This method uses extreme heat to make metals more malleable. Boron steel, for example, is heated to over 1,700°F and then quenched in a die. The result is a component that is both lightweight and exceptionally strong—ideal for safety-critical automotive and aerospace parts.

2. Progressive Metal Stamping

In progressive die stamping, the metal strip passes through multiple stations, with each station performing a different action. The result is a finished part cut from the strip at the end of the line.

- Best for high-volume production

- Reduces material waste

- Delivers fast turnaround times

- Ideal for parts requiring multiple forming steps

3. Precision Metal Stamping

Precision stamping is used for intricate or highly detailed designs where tolerances must be extremely tight.

- Can achieve tolerances as small as 0.0005 inches

- Perfect for electronics, medical devices, prototypes, and aerospace parts

- Produces consistent results with fewer steps in the process

What Is Custom Metal Stamping?

While standard stamping works for many applications, some industries need parts that are uniquely tailored. That’s where custom metal stamping comes in.

Custom stamping allows manufacturers to control every variable:

- Design – unique shapes, holes, or patterns

- Materials – brass, stainless steel, copper, aluminum, and more

- Finishes – coatings, platings, or polishing for corrosion resistance and appearance

- Tolerances – exact specifications for critical dimensions

Custom stamping is particularly valuable for:

- Medical devices – precision parts with strict regulatory standards

- Automotive components – lightweight yet strong designs

- Electronics – connectors, insulators, and battery parts

- Prototyping – low-volume runs to test designs before mass production

Material Selection in Metal Stamping

The material you choose impacts strength, cost, and performance. Some commonly used materials include:

- Stainless Steel – corrosion-resistant and durable

- Aluminum – lightweight and versatile

- Brass – excellent conductivity and formability

- Copper – ideal for heat-sensitive or conductive applications

- Specialty Alloys – for unique industry requirements

By consulting with a stamping specialist early in the design process, you can choose the best material for your project and avoid costly redesigns later.

Secondary Operations

Metal stamping doesn’t stop at forming. Many projects also require secondary operations to complete the part:

- Trimming

- Deburring

- Welding

- Coating or plating

- Heat treating

- Polishing

These steps improve performance, enhance appearance, and ensure parts are safe and ready for end use.

FAQs About Custom and Standard Metal Stamping

What’s the difference between precision stamping and custom stamping?

Precision stamping focuses on tight tolerances and fine details, while custom stamping is about tailoring the part’s overall design, material, and finish to specific needs.

Is custom stamping only for large orders?

No. Many manufacturers offer short-run stamping for prototypes or low-volume needs. This helps companies test designs before scaling up.

Which industries benefit most from custom stamping?

Automotive, aerospace, medical, and electronics are among the top industries, but nearly any manufacturer needing unique parts can benefit.

Key Takeaways

- Metal stamping is a fast, reliable way to manufacture parts with consistency.

- Common types include hot stamping, progressive stamping, and precision stamping.

- Custom metal stamping gives industries the flexibility to design parts that meet strict specifications and unique applications.

- Material selection and secondary operations are critical to achieving the best performance.

Partner with Fox Valley Stamping

Whether you need high-volume production, a prototype run, or a highly customized solution, Fox Valley Stamping can help. We specialize in short-run stampings, CNC laser cutting, and metal fabrication, delivering quality parts across industries.

👉 Contact us today to discuss your project and see how our stamping expertise can bring your designs to life.