Laser Welding vs MIG vs TIG: Which Process Is Right for Your Part?

If you’re sourcing fabricated metal parts, you’ve likely come across laser welding, MIG welding, and TIG welding. But which process is best for your application—and how do you know without being a welding expert?

At Fox Valley Stamping, we help customers choose the best welding method based on material, part thickness, cosmetic expectations, and function. You tell us what success looks like—we’ll handle how it gets done.

What’s the Best Welding Method for Your Material and Part Requirements?

You don’t need to pick the process—you need to define the requirements.

Here’s what we need from you to make an informed recommendation:

- Type and thickness of material(s)

- Functional intent (e.g., structural strength, leak-tight seam, cosmetic edge)

- Flatness or distortion limits

- Cosmetic expectations (visible seams, no grinding, brushed finish, etc.)

- Post-weld finish (powder coat, e-coat, anodize, none)

- Inspection method (visual, leak test, CMM, dye-pen)

- File formats (STEP + PDF with GD&T)

- Expected annual volume and production lot size

Once we have this info, we select the welding process—laser, MIG, TIG, or a hybrid—that meets your goals with the lowest total cost.

When to Use Laser Welding for Thin Sheet Metal or Stainless Parts

Laser welding is ideal when you need:

- Minimal heat input

- Tight seams on thin-gauge metal (typically 24–11 ga)

- Low distortion

- Clean, cosmetic welds

- Fast, repeatable cycle times

Best applications:

- Stainless steel panels and enclosures

- Consumer or medical products with visible seams

- Parts requiring minimal post-weld grinding

- Precision assemblies that must remain flat

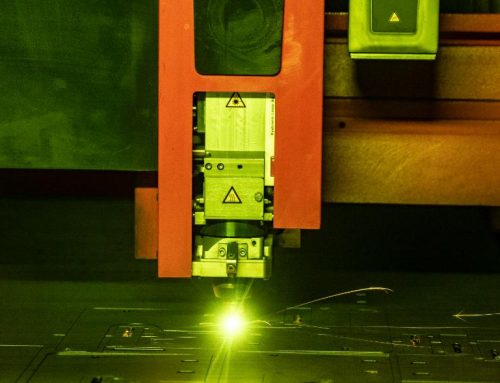

Because of the focused energy of fiber lasers like our LightWELD 1500 system, laser welds are incredibly clean and can eliminate rework and warping, especially on brushed stainless.

When MIG Welding Is Better for Strength and High Deposition Rates

MIG (Metal Inert Gas) welding is preferred when parts:

- Are thicker—typically 3/16″ and up

- Require strong, structural welds

- Allow for moderate cosmetic requirements

- Need fast metal deposition

Best applications:

- Brackets, frames, supports

- Carbon steel parts with generous fillets

- High-volume production where strength and speed matter

- Weldments that are hidden or painted

MIG is cost-effective and forgiving for larger assemblies where fit-up gaps and speed are more important than appearance.

When TIG Welding Is the Right Choice for Precision and Cosmetic Welds

TIG (Tungsten Inert Gas) welding offers the highest control and cleanest arc, making it ideal for:

- Very thin or delicate parts

- Welds with tight access

- Applications requiring perfect cosmetics

- Difficult-to-weld alloys like aluminum or copper

Best applications:

- Instrument housings

- Aerospace components

- Complex geometries or tight-tolerance joints

- Visible parts where bead quality is critical

Although TIG is slower, it excels at delivering precise, clean welds with minimal spatter—perfect when the weld is part of the final product’s appearance.

| Performance Factor | Laser Welding | MIG Welding | TIG Welding |

|---|---|---|---|

| Distortion Control | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Cosmetic Appearance | ★★★★★ | ★★☆☆☆ | ★★★★★ |

| Speed on Long Seams | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Thick Section Welding | ★★★☆☆ | ★★★★★ | ★★☆☆☆ |

| Precision & Tight Access | ★★★☆☆ | ★★☆☆☆ | ★★★★★ |

| Material Flexibility | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Post-Weld Cleanup Required | ★☆☆☆☆ | ★★★☆☆ | ★★☆☆☆ |

| Best Use Case | Cosmetic panels | Structural parts | Precision welds |

Note: Process selection should be based on part geometry, material, and final use—not just appearance or thickness alone.

What Buyers Should Include in an RFQ for Welded Metal Parts

To get accurate pricing and the right weld process, include this info in your RFQ:

- Material type and thickness

- Weld joint type and functional requirement

- A-side/B-side cosmetics or grinding restrictions

- Flatness tolerances or warp limitations

- Post-weld surface finish requirements

- Expected inspection method

- Annual usage and production batch sizes

- File types (STEP + PDF with dimensions and tolerances)

✅ Bonus Tip: Don’t specify the welding method on your print. Instead, describe the outcome you need—strength, cosmetics, flatness—and we’ll select the best approach.

Design Tips to Minimize Weld Cost and Improve Cosmetic Outcomes

Small adjustments to your part design can make a big impact on quality and cost:

- Use self-fixturing features (tabs, slots, nests) to reduce clamping and improve alignment.

- Identify the “show face” so seams are placed on the hidden side where possible.

- Avoid over-specifying flatness—we’ll work with your team to meet functional limits.

- Design with finish in mind—some welding methods reduce or eliminate sanding before powder coat or anodize.

Want a weldment that’s flat, clean, and easy to finish? Let’s collaborate early in the design.

Real-World Example: How Laser Welding Eliminated Warping and Rework

Challenge: A 16-gauge stainless steel enclosure was warping after MIG welding. Each unit required 20–30 minutes of rework to flatten and grind.

Solution: Fox Valley Stamping converted the process to laser welding and added self-locating features to the cut flat.

Result:

- Warping eliminated

- Post-weld grind time reduced to 0

- Enclosure passed flatness inspection without adjustment

- Cosmetic finish preserved

- Lead time reduced by 3 days

This is a prime example of how process selection + smart DFM saves time and money without changing the part itself.

FAQs: Choosing the Right Welding Process for Metal Fabrication

Do I need to specify MIG, TIG, or laser welding on my print?

No. Just define your requirements (cosmetics, strength, distortion) and we’ll recommend the best method.

Can you mix welding processes on one part?

Absolutely. We often use laser for visible seams and MIG for hidden structural joints.

Will powder coat or anodize hide weld marks?

They hide color variation but not deep grind lines or rough beads. That’s why we often recommend laser or TIG for cosmetic welds.

What if I only have a PDF and not a STEP file?

We can work with it, but STEP files allow us to better analyze geometry, fit-up, and fixturing needs.

Get Expert Welding Recommendations for Your Next Project

You don’t have to guess which welding process is best—we’ll handle that for you.

Just send us your STEP and PDF files along with any notes on cosmetic expectations, tolerances, or finishing. Our team will evaluate your design and recommend the best-fit welding method—laser, MIG, TIG, or a hybrid approach.

👉 Ready to quote a weldment? Upload your files to Fox Valley Stamping and get expert feedback from our fabrication team.