There are several sheet metal fabrication processes available, but the most common ones are folding, cutting, and punching. Depending on the type of metal and its thickness, any of these methods can be used with each having different advantages. Different processes or a combination of fabrication process will be used to create a finished product.

Metals Used in Fabrication

There are several types of sheet metals used in fabrication processes. Most common types of sheet metal are made from steel, aluminum, zinc, copper, and stainless steel. These metals are usually 0.006 to 0.25 inches thick. The thinner gauges are more malleable, while the thicker ones are best for heavier-duty parts. Many specialist industries rely on sheet metal fabrication to create a wide range of components. This process is an excellent alternative to casting and produces minimal waste.

Cutting

Basic cutting is the most basic form of fabrication. The blade is placed on the metal to cut it into the desired shape. Stamping may be the first process in the fabrication process, or it can be the only step. Similarly, shearing involves two blades that move together in a circular motion. The lower blade is stationary, while the upper one lowers. A similar technique is brazing, which uses a metal wire to melt a metal part

Laser cutting is another type of sheet metal fabrication process. This method provides smooth edges without leaving metal chips behind. Unlike other sheet metal fabrication processes, it is also a cost-effective option for mass production. It can be used at room temperature, so there’s no need to preheat the material. Shearing, for example, can also be used for the fabrication of non-industrial products. Finally, basic cutting is the most common process. It uses a single blade to cut a sheet of metal.

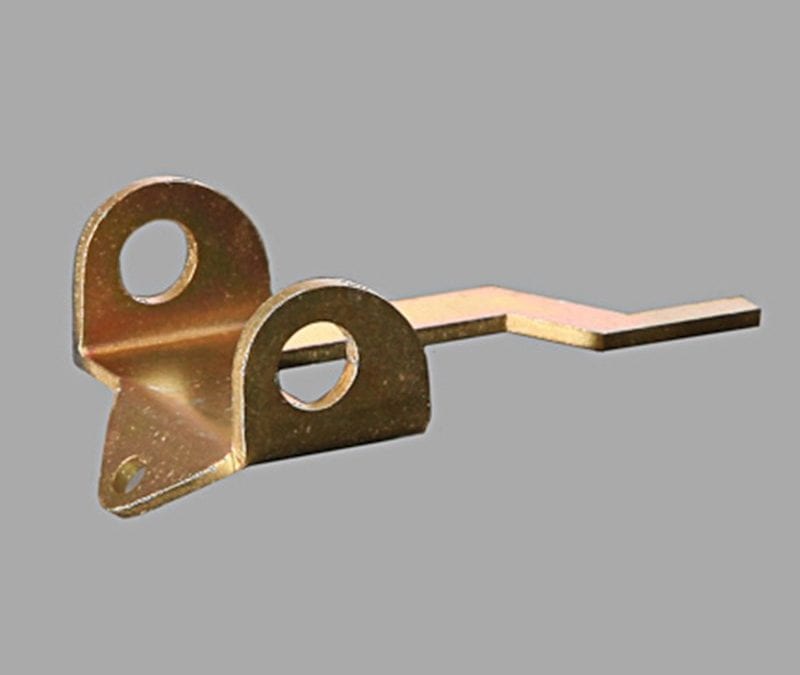

Punching

The first process of metal fabrication is punching. It uses a hollow die to punch a hole in the metal. A punch press against the metal forces the shape through the metal. Then, a die removes the excess material. The second process is extrusion, which involves a tool that cuts multiple slits in the sheet. Generally, sheet metal is pressed into shapes or stretched open.

Welding

One a metal component is cut or punched from sheet metal, the fabrication process may require joining metal pieces. There are different types of joining with the primary ones being MIG and TIG welding. MIG welding is best used on thinner metal and works well joining works metals such as stainless steel, aluminum, and copper. TIG welding produces higher quality welds and requires more skill than MIG welding.

There are various types of sheet metal fabrication processes. Metalworking specialists at Fox Valley Stamping have the expertise to deliver high quality precision parts using the latest fabrication techniques. We provide innovative solutions for short run stamping, metal fabrication, and LASER cutting needs. Contact us today!

847.741.2277

847.741.2277