CNC Laser Cutting Process in 2025

CNC Laser Cutting in 2025: What It Is and Why It Matters for Your Next Project

If you need fast, accurate, and clean cuts on metal parts, CNC laser cutting is one of the most efficient methods available today. Whether you’re creating prototypes, custom components, or full production runs, laser cutting offers unmatched precision—and in 2025, it’s more advanced than ever.

At Fox Valley Stamping Company, we combine cutting-edge laser technology with decades of fabrication experience to deliver consistent, high-quality results on every project.

What Is CNC Laser Cutting?

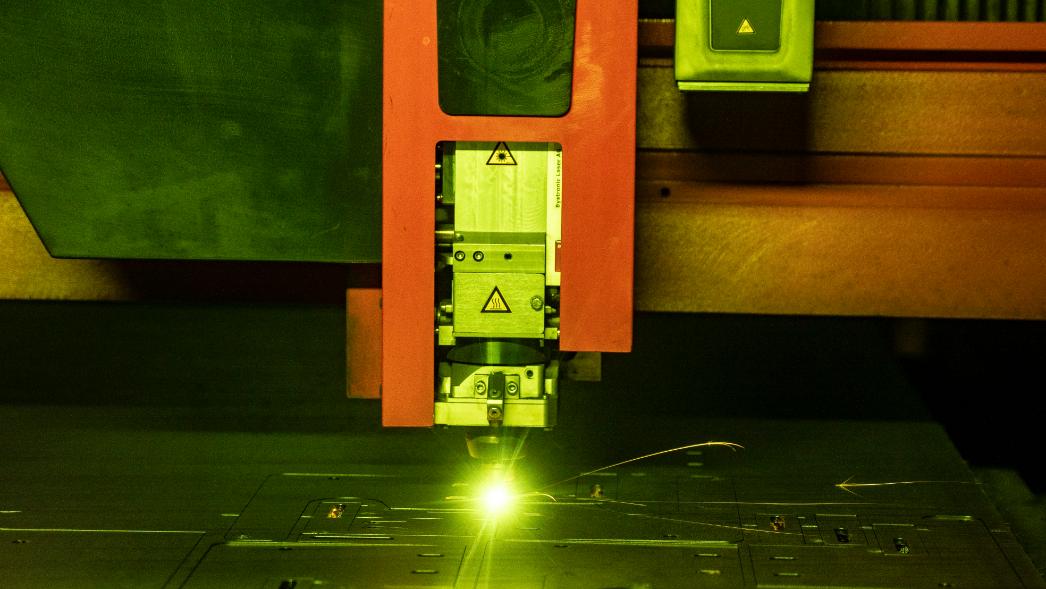

CNC (Computer Numerical Control) laser cutting is a fabrication process that uses a high-powered laser beam directed by a computer to cut, engrave, or etch material—usually metal. The laser melts, burns, or vaporizes material along a programmed path, producing smooth, burr-free edges with exceptional detail.

Think of it as drawing with light, but on steel, aluminum, or stainless materials—quickly and precisely.

Why Use CNC Laser Cutting?

Here’s why CNC laser cutting is a top choice for manufacturers and engineers in 2025:

-

Incredible Precision: Cut intricate shapes and tight tolerances—ideal for complex or custom parts.

-

Speed and Efficiency: Fast cutting with minimal setup means shorter lead times and lower costs.

-

Clean Edges: No need for secondary deburring or finishing in most cases.

-

Material Versatility: Works with cold rolled steel, hot rolled steel, stainless steel, aluminum, and more.

-

Repeatability: Perfect for short-run stamping or repeat production with consistent quality.

Our Capabilities at Fox Valley Stamping

We use high-performance CNC laser cutting equipment to deliver quality parts at scale. Our machines are optimized for:

-

Mild steel up to 1” thick

-

Stainless steel up to 0.5”

-

Aluminum up to 0.375”

-

Tight tolerance requirements

-

Custom designs, prototypes, and production quantities

Need a bracket, panel, frame, or a custom part with cutouts? Our experienced team works closely with you to meet exact specifications and deadlines.

Laser Cutting vs. Traditional Cutting

Compared to mechanical cutting methods like sawing or punching, CNC laser cutting offers:

-

Less material waste

-

Faster setup and processing

-

Higher precision on complex geometries

-

Cleaner cuts, reducing the need for post-processing

Industries We Serve

From agriculture and construction to medical and industrial manufacturing, laser cutting plays a vital role in component fabrication. Our clients value speed, reliability, and quality—and that’s what we deliver.

Ready to Get Started?

If your project demands accuracy, speed, and a partner you can rely on, Fox Valley Stamping is here to help. Whether you need a one-off prototype or full production support, our CNC laser cutting services are designed to make your job easier—and your products better.

📞 Call us today at 847-741-2277

🌐 Contact us to request a quote or speak with a fabrication expert.

Let’s cut through complexity—together.