Are you tired of compromising on quality when it comes to small production quantities? Short run precision metal stampings are here to revolutionize your manufacturing process.

Key Takeaways

- Short run stamping is a cost-effective process for producing complex metal parts in small quantities.

- It offers reduced production and material costs, less waste, and reduced lead times compared to traditional manufacturing methods.

- Short run stamping is ideal for industries such as aerospace, automotive, electronics, and medical.

- It is suitable for prototypes and small quantities for testing and initial production runs.

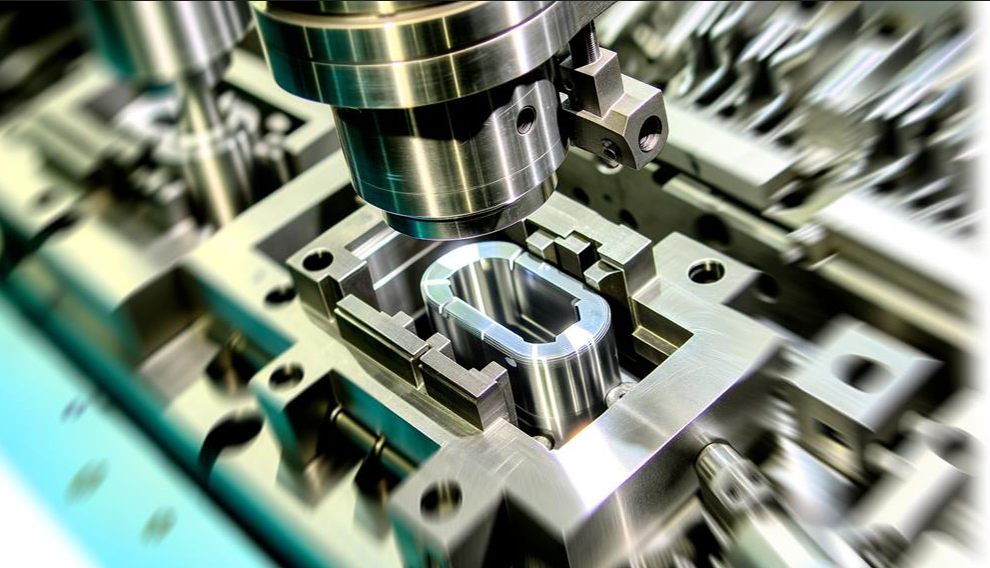

WHAT IS SHORT RUN STAMPING?

It is a cost-effective and efficient process for producing complex metal parts in small quantities. It involves production runs of 5,000 parts or fewer over six months or less. Various metals like aluminum, steel, and brass can be used in the short run stamping process. This method offers many benefits, including reduced production and material costs, less waste, and reduced lead times.

Short-run stamping is ideal for applications such as aerospace, automotive, electronics, and medical industries. It’s a versatile technique that allows for the creation of highly complex and accurate parts. Compared to long run stamping, which is used for larger production quantities, short run offers quicker turnaround times and the ability to produce customized metal parts in smaller quantities.

The cost benefits are significant. By producing in smaller quantities, companies can reduce their production costs and minimize material waste. Additionally, the reduced lead times allow companies to respond quickly to market demands and make necessary adjustments to their designs.

WHAT ARE THE ADVANTAGES OF SHORT RUN STAMPING?

Reducing production costs, material waste, and lead times, short run stamping offers several advantages for companies in industries such as aerospace, automotive, electronics, and medical.

Here are the advantages of short run stamping:

- Reduced costs: Short run stamping is cost-effective for small production quantities, allowing companies to save money compared to traditional manufacturing methods.

- Customizable designs: Short run stamping enables companies to create complex and accurate parts according to customer specifications, providing a high level of customization.

- Efficient production: Short run stamping allows for quick turnaround times, making it an ideal choice for companies that require fast production of metal parts.

- Material flexibility: Short run stamping can utilize various metals such as aluminum, steel, and brass, providing flexibility in material selection for different applications.

- Prototype development: Short run stamping is suitable for prototypes and smaller quantities, allowing companies to test and refine designs before full-scale production.

WHEN SHOULD I USE SHORT RUN STAMPING?

When considering cost-effective production for prototyping and smaller quantities, short run stamping is an ideal choice. It offers several advantages that make it a budget-friendly option for companies in need of complex and accurate metal parts.

Short run stamping is particularly suitable for projects with smaller budgets and quicker turnaround times. With short run stamping, you can minimize tooling expenses and reduce waste, making it a cost-effective solution.

Additionally, short run stamping is perfect for highly complex and intricate designs that require precision and accuracy. It’s capable of producing symmetrical parts such as engine cylinders and fire extinguisher housings with ease.

Short Run Stamping Services

Looking for metal parts in small production quantities? Look no further than Fox Valley Stamping for our exceptional short run stamping services. Our precision metal stampings offer cost-effectiveness, quick turnaround times, and the ability to create complex and accurate parts. Choose Fox Valley Stamping for short run precision metal stampings and experience the difference today. Contact us for a quote or to learn more about our services.

847.741.2277

847.741.2277